CVL / Airway Cart Restocking for Patient Charge Items

A Kaizen from East Tennessee Children’s Hospital and their PICU. Here is an example that is good for patients and staff (less delay) and is good for the organization (better charge capture).

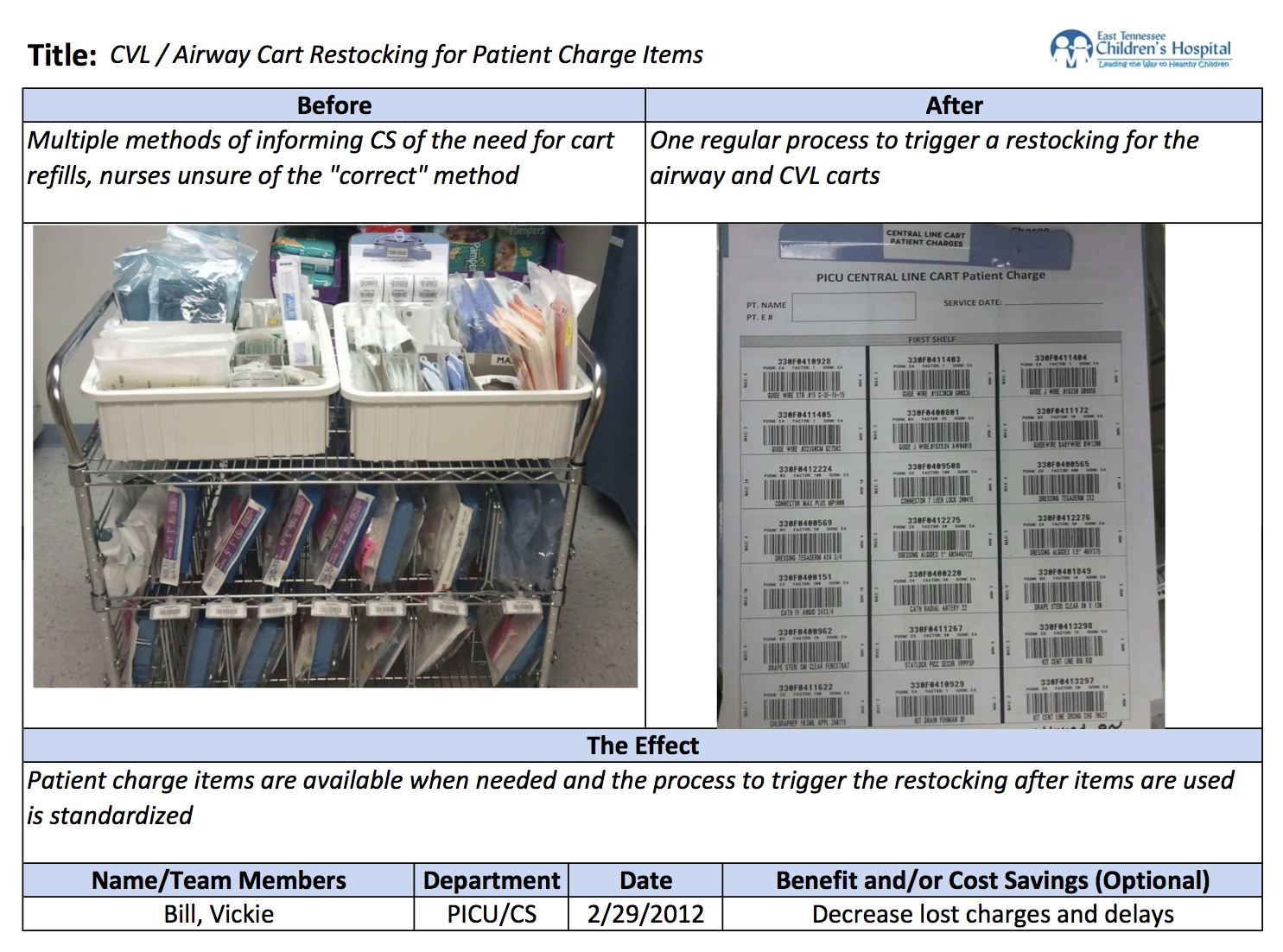

Before there were multiple methods of informing Central Supply of the need for cart refills. Nursing could call down to Central Supply, fax a tick sheet or transport the cart to the bar code reorder workstation. The nurses were unsure of the “correct” method of ordering. This caused confusions for both Central Supply staff and the PICU nurses. Now the Central Supply and PICU nurses worked together to create one method that works for both departments. Patient charges are now captured on a charge sheet and entered into the reorder workstation without moving the cart.